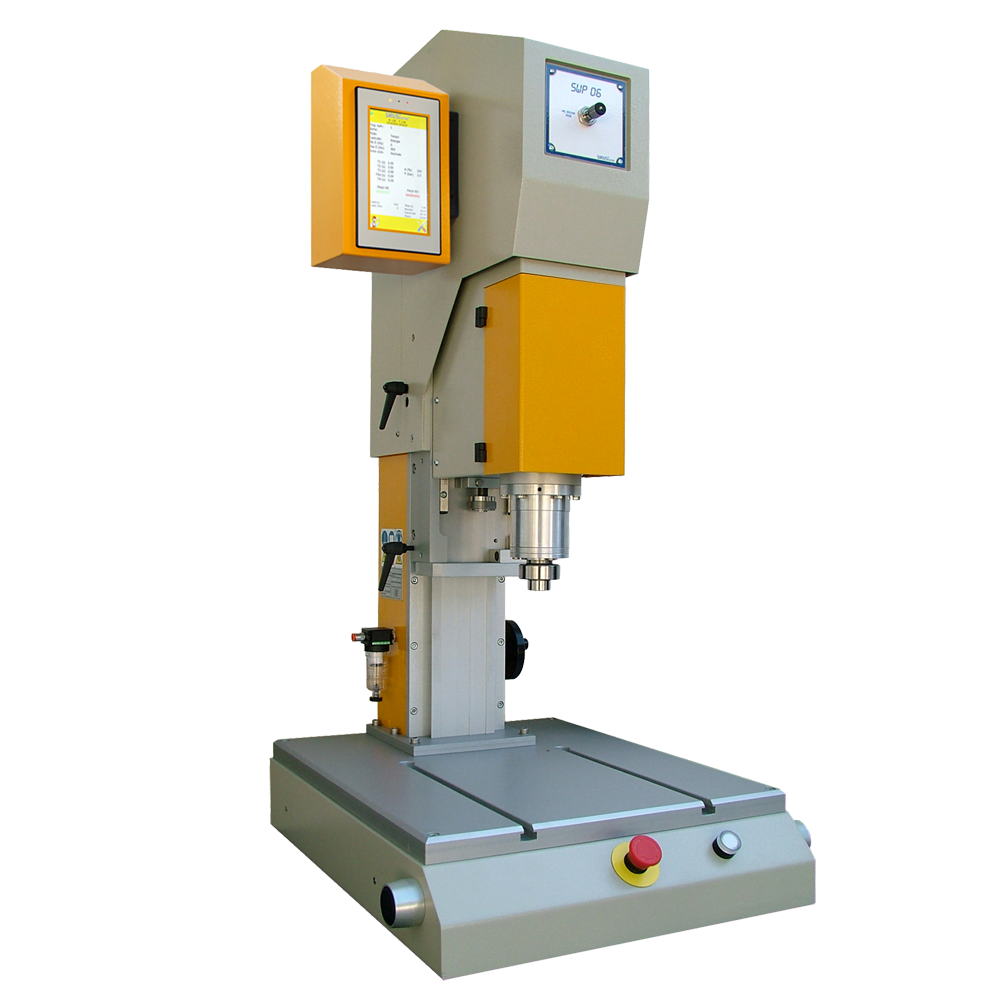

The SWP 06 spin welder was designed and manufactured using state-of-the-art technologies.With this technology, most thermoplastic materials having a round shape can be welded.

SWP-06

Out of stock

Description

For spin welding technology, the heat needed to melt the parts is produced by a rotating motion combined with thrust pressure. One of the parts to be welded is held by a fixture, while the other one is set in motion by a rotating spindle.

One of the most important features of this welder is the cycle control system managed by TOUCH SCREEN MICROPROCESSOR

| Supply voltage | 400 V – 50 Hz |

| Absorption | 4 A |

| Motor power | 2 KW |

| Motor torque | 3,8 Nm max. |

| Motor revolutions | 6000 RPM max. |

| Cylinder head down | 63 mm. diam. |

| Stroke | 100 mm. max. |

| Thrust pressure | 180 Kg. Max. |

| Dimensions | 600x500x1200 mm. |

| Working table | 600×500 mm. |

| Operating modes | Time –distance angle |